The story behind the beautiful glass buttons

Around 1760, the production of glass buttons starts in Europe with the invention of the metal mould. After this, things go fast, and glass buttons are produced for all kinds of clothing, children's clothes, fine suits and uniforms.

During the Second World War, many of the glass manufacturers had to stop production, after which the cheap, popular plastic buttons from Asia gained ground on the market.

Today, there are only a few who know the noble craft of molding a glass button.

Glass colors

The glass in the beautiful buttons originates from European mountains, where limestone and silicon are mined, creating the neutral, transparent glass. Metals are then added to conjure up the beautiful colors, and the glass is shaped into long rods.

The glass buttons are cast manually

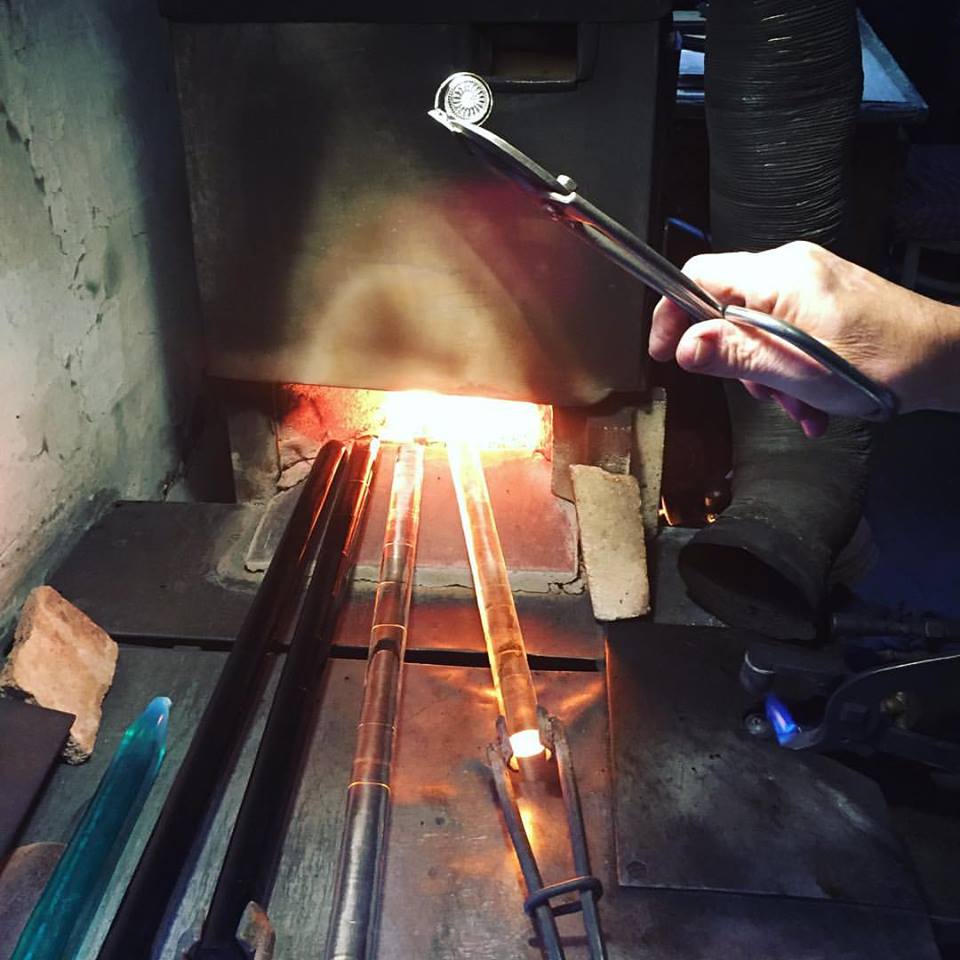

The glass rods are heated at high temperatures until the outermost part of the rod begins to melt so that it can flow down into the mold. It is a very slow process, which takes place manually to ensure that each button is absolutely perfect.

The molds

Most of the unique molds used for glass buttons are over a hundred years old. Over the years, they have cast many beautiful buttons. I am proud that we can still use the old forms of production.

Finishing the glass buttons

Once the buttons are cast, there is still a long way to go before they can be put on the clothes. They must be polished and sanded in water to avoid sharp edges. The buttons must have a soft surface and rounded edges.

Hand painted glass buttons

Once the buttons have been polished, they are finished. Now they can remain as they are with their fine colors and patterns or they can be further refined by applying elegant decorations with small brushstrokes. This makes them completely unique.

Finally, the hand-painted buttons must be burned again to fix the paint, before they can be mounted on the garment.